+86-519-83387581

Screen printing technology has become a vital component in various industries, particularly for applications involving sheet materials. From transfer printing labels to dashboard panels and large display screens, the versatility and precision of screen printing equipment make it an indispensable tool for manufacturers looking to deliver high-quality products.

Key Applications of Screen Printing Equipment

1. Transfer Printing Labels: Transfer labels are crucial for branding and product identification across numerous sectors, including retail and packaging. Screen printing allows for the creation of vibrant and durable labels that can withstand different environments. This process ensures that intricate designs and logos are reproduced with accuracy, making labels not only functional but also visually appealing.

2. Dashboard Panels: The automotive industry heavily relies on screen printing for dashboard panels, where clarity and durability are essential. Screen printing equipment can produce precise graphics, icons, and text on various materials used in dashboard manufacturing. The ability to print multiple layers adds depth and visual interest while ensuring the final product can endure exposure to heat, moisture, and UV light.

3. Large Display Screens: As demand for large display screens grows in advertising, trade shows, and retail spaces, the need for efficient printing solutions has become paramount. Screen printing is well-suited for these applications, enabling manufacturers to print large graphics with consistent quality. This technology can handle large sheets and various substrates, providing flexibility in design and production.

Advantages of Screen Printing for Sheet Materials

1. High Precision and Detail: One of the main benefits of screen printing is its ability to deliver high precision and detail. The technology allows for the reproduction of intricate designs and fine lines, making it ideal for complex graphics found in labels, dashboard panels, and display screens.

2. Material Versatility: Screen printing equipment can work with a wide range of materials, including vinyl, plastic, metal, and glass. This versatility enables manufacturers to adapt to various customer needs and create products tailored to specific applications.

3. Cost-Effective for Large Runs: For businesses focusing on high-volume production, screen printing is cost-effective. The use of reusable stencils reduces material costs and setup time, making it an efficient choice for bulk orders.

Future Trends in Screen Printing for Sheet Materials

As technology advances, the screen printing industry is evolving. Key trends include:

1. Integration of Automation: Automation is revolutionizing screen printing processes, improving efficiency and reducing labor costs. Automated systems can streamline production lines, ensuring consistent quality and faster turnaround times.

2. Sustainable Practices: There is a growing emphasis on sustainability within the printing industry. Manufacturers are increasingly seeking eco-friendly inks and processes that minimize waste, catering to environmentally conscious consumers.

3. Enhanced Digital Integration: The integration of digital technology with traditional screen printing is gaining traction. Hybrid systems that combine screen printing with digital processes can offer greater flexibility and customization, allowing for on-demand printing solutions.

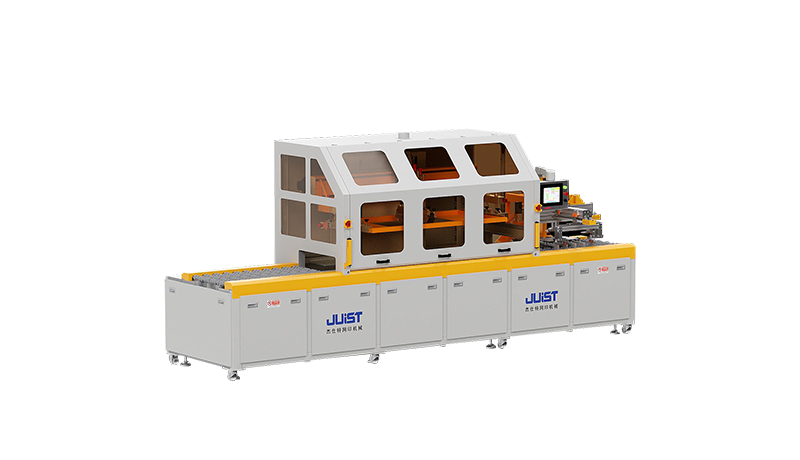

JST5070 Automatic Separation Device

Screen printing equipment is essential for producing high-quality sheet materials, including transfer labels, dashboard panels, and large display screens. With its precision, versatility, and cost-effectiveness, screen printing continues to be a preferred method for manufacturers across various industries. As the market evolves with advancements in technology and sustainability practices, screen printing is poised to remain a key player in the production of visually impactful and durable products.

We invite you to visit JUIST to reserve your sheet material screen printing equipment. For more information you can also reach us on WhatsApp: +86 18101500471 or via email at sales@juistmac.com.