+86-519-83387581

With the rapid development of science and technology, the rapid development of 3C electronic products has brought challenges to the manufacturing process. As one of the core equipment for precision manufacturing in this field, 3C electronic screen printing machines have become an important force in promoting innovation and upgrading of the electronics industry with their precision manufacturing capabilities and ingenious design concepts.

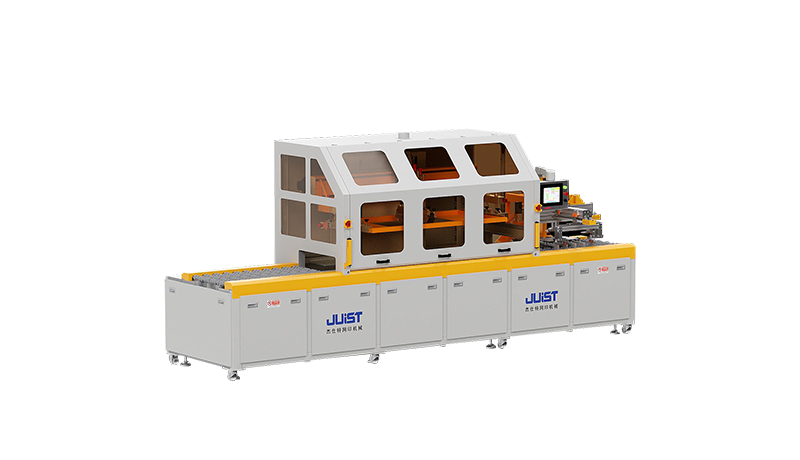

3C electronic screen printing machines are designed for the three major fields of consumer electronics, communication electronics and computer electronics, integrating advanced technologies in multiple fields such as precision machinery, electronic control, materials science and information technology. The core is to accurately print conductive inks, insulating inks or other functional materials on the surface of tiny and complex substrates through precise screen plates to form fine circuit patterns or component identification.

To achieve this goal, 3C electronic screen printing machines use a number of cutting-edge technologies. The high-precision positioning system ensures that each print can achieve micron-level accuracy, meeting the stringent requirements of electronic components for position accuracy. The intelligent control system can automatically adjust the printing speed, pressure and angle according to preset parameters to achieve an efficient and stable production process. The advanced ink recovery and purification system not only ensures the printing quality, but also reflects the design concept of environmental protection and energy saving.

The manufacturing process of 3C electronic screen printing machine is itself an ultimate pursuit of precision and ingenuity. From material selection to parts processing, from assembly and debugging to performance testing, every link embodies the wisdom and sweat of engineers. In terms of material selection, manufacturers strictly select high-strength, high-wear-resistant and corrosion-resistant high-quality materials to ensure that the equipment still maintains performance during long-term operation. In terms of parts processing, high-precision CNC machine tools are used for precision processing to ensure that the dimensional accuracy and surface quality of each component meet the design requirements.

The assembly and debugging stage is a test of ingenuity. Engineers need to patiently and carefully adjust the position and gap of each mechanical component to ensure that they can fit closely and run smoothly. At the same time, the control system needs to be repeatedly debugged and optimized to ensure that the equipment can accurately perform printing tasks according to the preset parameters. Although this process is cumbersome and time-consuming, it is this ingenuity that enables 3C electronic screen printing machine to stand out in the fierce market competition.

The widespread application of 3C electronic screen printing machines has brought significant advantages to the electronics manufacturing industry. High-precision printing technology ensures the performance and reliability of electronic components, and provides more sophisticated and stable circuit connections for 3C products such as smartphones, tablets, and wearable devices. This not only enhances the market competitiveness of products, but also brings consumers a better user experience.

With the continuous development and integrated application of technologies such as the Internet of Things, big data, and artificial intelligence, 3C electronic screen printing machines will usher in a broader development prospect. On the one hand, it will be more closely integrated into the intelligent manufacturing system to achieve comprehensive monitoring and optimization of the production process; on the other hand, with the continuous advancement of materials science and technology and the development and application of new functional inks, it will bring more diversified application scenarios and higher levels of manufacturing capabilities to the electronics manufacturing industry.