+86-519-83387581

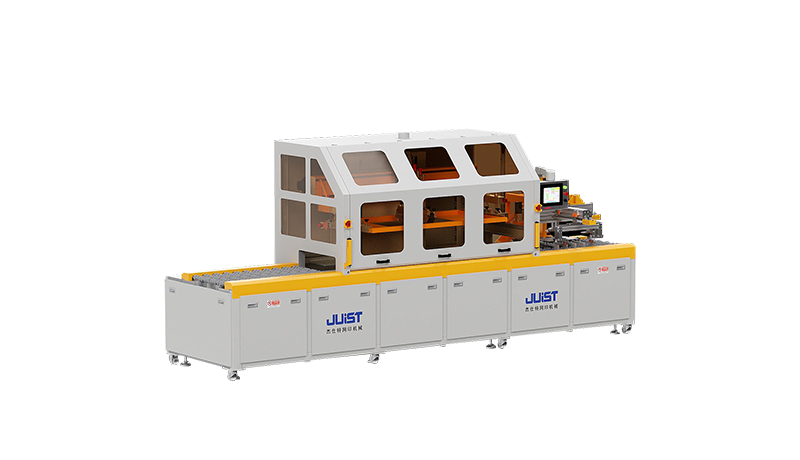

UV curing machine is a device that uses ultraviolet light source to quickly cure coatings, inks or adhesives. During the curing process, the material to be cured needs to be fed into the UV curing machine and cured under ultraviolet light. The traditional manual feeding method is not only inefficient, but also prone to uneven curing or material damage due to human factors. In order to improve production efficiency and ensure curing quality, UV curing machines are usually equipped with automatic feeding systems.

The automatic feeding system realizes the automatic feeding and delivery of the material to be cured through a series of mechanical devices and sensors. When the UV curing machine is started, the automatic feeding system will take out the material to be cured from the storage area or the previous process according to the preset program and parameters, and accurately feed it into the UV curing machine. During the curing process, the system will adjust the feeding speed and position according to the size and shape of the material to ensure that the material can be evenly exposed to ultraviolet light. After the curing is completed, the automatic feeding system will take the material out of the UV curing machine and send it to the next process or storage area.

In order to meet the needs of different industries and application scenarios, the automatic feeding system can also be customized according to production needs. For example, in the printing industry, due to the different sizes and shapes of printed materials, the automatic feeding system is usually equipped with devices such as conveyor belts and lifting mechanisms to adapt to materials of different sizes and weights. These devices can be adjusted according to the size and shape of the material to ensure that the material can remain stable and accurate during the feeding process.

The application of the automatic feeding system not only improves the production efficiency of the UV curing machine, but also significantly reduces the labor intensity of the operator. The traditional manual feeding method requires operators to repeat tedious operations, which is not only easy to fatigue, but also prone to errors. The automatic feeding system can liberate operators from tedious work through automation and intelligence, allowing them to focus on more important tasks, such as monitoring equipment status, adjusting curing parameters, etc.

In addition, the automatic feeding system is also highly flexible and scalable. With the changes in production needs and the continuous advancement of technology, the automatic feeding system can be upgraded and modified to adapt to new production needs and technical requirements. This enables the UV curing machine to always maintain an efficient and stable production state, providing strong support for the production and development of the enterprise.