+86-519-83387581

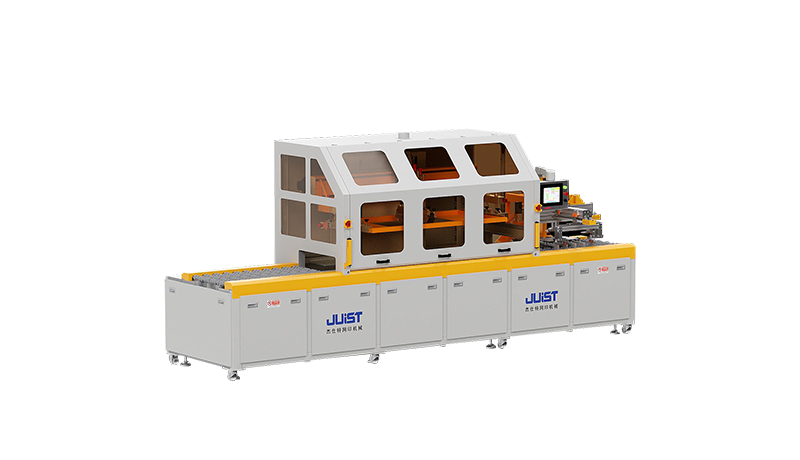

In the rapidly developing photovoltaic industry, every production process is crucial, and photovoltaic glass tape laminating, as a key link, directly affects the performance and life of photovoltaic modules. The automatic photovoltaic glass tape laminating machine, as the core equipment in this link, has become an important force in modern photovoltaic production lines with its excellent performance and efficient automation level. The high-quality tape usually equipped with this machine provides a solid guarantee for the long-term use safety of photovoltaic glass.

High-quality tape: the "invisible guardian" of the photovoltaic industry

The tape used by the automatic photovoltaic glass tape laminating machine is incomparable to ordinary materials. These tapes have been carefully selected and rigorously tested, and have a series of excellent properties: first, adhesion. High-quality tapes can fit tightly to the surface of photovoltaic glass to form a stable bonding layer, effectively resisting the impact and erosion of the external environment; second, weather resistance. Whether it is severe cold or hot or wind and rain, the tape can maintain stable performance, no fading, no degumming; finally, aging resistance. After long-term use, it can still maintain good physical and chemical properties and extend the service life of photovoltaic modules. These characteristics make high-quality tapes the "invisible guardian" of the photovoltaic industry, silently guarding the safety and stability of each piece of photovoltaic glass.

Optimizing the lamination process: the crystallization of technology and innovation

In order to further improve the lamination quality, the automatic photovoltaic glass tape laminating machine has carried out continuous research and development and optimization in the lamination process. On the one hand, the use of advanced lamination technology and equipment, through precise mechanical analysis and calculation, ensures that the tape can be evenly stressed during the lamination process. This not only avoids quality problems such as bubbles and wrinkles caused by uneven force, but also greatly improves the lamination efficiency and accuracy. On the other hand, new intelligent control systems and detection technologies are constantly introduced to achieve real-time monitoring and feedback of the lamination process. Once an abnormal situation is found, the system can immediately make adjustments or issue an alarm to ensure the stability and reliability of the lamination quality.

Future trend of full automation

With the continuous development and upgrading of the photovoltaic industry, the automatic photovoltaic glass tape laminating machine is moving towards a more intelligent and efficient direction. In the future, we are expected to see the application of more innovative technologies, such as artificial intelligence, big data analysis, etc., to further improve the automation level and intelligence of the laminating machine. At the same time, with the continuous improvement of environmental protection and sustainable development requirements, environmentally friendly and energy-saving tapes will become an important direction for future development. These efforts will not only promote the technological progress and industrial upgrading of the photovoltaic industry, but also make important contributions to the optimization of the global energy structure and the improvement of the environment.

Automatic photovoltaic glass tape laminating machines and their equipped high-quality tapes are an indispensable and important part of the photovoltaic industry. They continuously improve the quality and efficiency of lamination through the power of science and technology and innovation, and provide a solid guarantee for the long-term use and safety of photovoltaic glass. In the future, with the continuous advancement of technology and the continuous expansion of applications, we have reason to believe that the photovoltaic industry will usher in a more brilliant development prospect.