+86-519-83387581

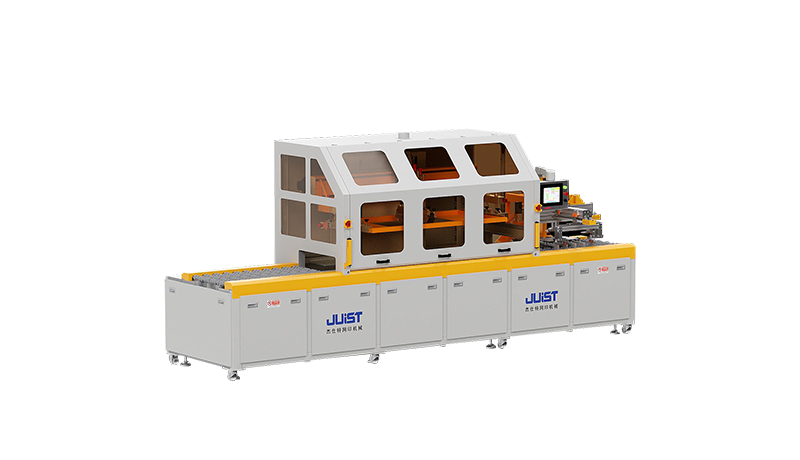

The automatic positioning and alignment system of the Screen Printing Machine For Glass during printing is one of its core functions, which ensures that the pattern can be accurately printed at the specified position on the glass surface.

1. System composition

The automatic positioning and alignment system usually consists of high-precision sensors, mechanical transmission devices, control systems, and software algorithms. These components work together to achieve accurate positioning and alignment of the glass substrate and the screen.

2. Workflow

Initialization settings:

Before starting printing, the operator needs to set the starting position, size, and specifications of the glass substrate through the control system. These parameters will be input into the control system as the basis for automatic positioning and alignment.

Glass substrate positioning:

When the glass substrate is fed into the printing area, the high-precision sensor will start working immediately. These sensors usually include photoelectric sensors, laser sensors, or mechanical limit switches, which can detect the position and posture of the glass substrate in real-time.

By comparing with the preset parameters, the control system calculates the deviation between the current position of the glass substrate and the ideal position and drives the mechanical transmission device to make corresponding adjustments until the glass substrate is accurately placed in the predetermined position.

Screen Alignment:

After the glass substrate is positioned, the next step is to align the screen. The screen carries the pattern to be printed, and its position must be accurately aligned with the target position on the glass substrate.

Similar to the positioning process of the glass substrate, the screen is also mounted on a movable bracket and positioned by high-precision sensors and control systems. The control system calculates the alignment position of the screen based on the preset pattern position and the actual position of the glass substrate and drives the mechanical transmission device to adjust it.

Fine-tuning and Locking:

After the initial positioning and alignment, the system usually performs fine-tuning operations to eliminate any minor deviations. This includes fine-tuning the position, angle, and distance of the glass substrate and the screen to ensure that the pattern can be printed on the glass surface in the state.

Once the alignment is achieved, the system locks the glass substrate and the screen in the current position to prevent movement or offset during printing.

Real-time monitoring and adjustment:

During the entire Screen Printing Machine For the Glass printing process, the automatic positioning and alignment system will continue to work, monitoring the position status of the glass substrate and the screen in real time. If any deviation or abnormality is detected, the system will immediately sound an alarm and automatically adjust to ensure the stability and consistency of the printing quality.

3. Technical advantages

High precision: The use of high-precision sensors and control systems can achieve micron-level positioning accuracy to meet the needs of high-precision printing.

Good stability: The system has strong anti-interference ability and stability, and can maintain stable performance in a complex working environment.

High degree of automation: Reduces the possibility of manual intervention and errors, and improves the production efficiency and product quality of the Screen Printing Machine For Glass.

Strong adaptability: It can adapt to glass substrates of different specifications and shapes and diversified pattern requirements, and has a wide range of application prospects.

The automatic positioning and alignment system of the Screen Printing Machine For Glass plays a vital role in the printing process. It realizes the precise positioning and alignment of the glass substrate and the screen through the collaborative work of high-precision sensors, mechanical transmission devices, control systems, and software algorithms, providing a strong guarantee for high-quality and efficient glass screen printing.