+86-519-83387581

Screen printing machines, officially known as “silk screen printing machines,” are devices that use a mesh screen to transfer ink or paste onto a substrate. They are widely applied in industries such as glass processing, electronic films, printed circuit boards, instrument panel markings, and solder paste printing for circuit boards. Based on their design and functionality, screen printing machines can be classified into the following categories:

1. Main Types of Screen Printing Machines and Their Features

- Vertical Screen Printing Machine

This type is ideal for high-precision printing, such as multicolor overprinting and halftone printing in high-tech electronic industries. While its efficiency is lower compared to slanted arm machines, its precision is unparalleled, making it a preferred choice for demanding applications.

Automatic (CCD) Sheet Screen Printing Machine

- Slanted Arm Screen Printing Machine

Designed for packaging industries or partial UV printing, this machine prioritizes efficiency over precision, making it suitable for high-speed production needs.

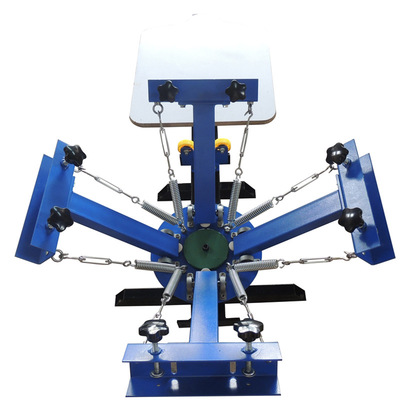

- Rotary Screen Printing Machine

Commonly used in the garment and optical disc industries, this machine is ideal for printing on items that are difficult to position accurately, thanks to its rotary design.

- Four-Column Screen Printing Machine

This machine caters to large-format printing requirements in industries such as photovoltaics, construction, and large-scale glass processing. Its four-column structure ensures better stability and precision.

Architectural & Engineering Glass Printing Machine

- Fully Automatic Screen Printing Machine

Specifically designed for roll-to-roll printing on flexible materials such as PET, PP, PC, and PE, this machine integrates feeding, printing, and drying processes into a single workflow. It is the go-to choice for mass production in modern industries.

Auto (CCD )Roll To Roll Screen Printing Machine

- Fully Automatic Oval Screen Printing Machine

Primarily used for printing on garment panels, it supports a variety of inks and pastes, including glue paste, water-based paste, and oil-based inks. This machine is ideal for the apparel industry, which demands versatility and high production efficiency.

2. Wide Range of Applications

Screen printing machines play an essential role across various industries:

- Glass Processing: Printing patterns or markings on glass surfaces.

- Electronic Film Industry: Used for precise circuit and conductive film production.

- Printed Circuit Boards (PCBs): Printing of insulating films, solder paste and markings to enhance performance.

- Garment Industry: Printing patterns on fabrics and garment panels.

- Packaging Industry: Facilitating rapid, high-volume printing for packaging materials.

3. Choosing a Professional Manufacturer

Changzhou JUIST Screen Printing Machinery Co., Ltd. specializes in manufacturing vertical screen printing machines, four-column screen printing machines, and fully automatic screen printing machines. The company also offers auxiliary products such as drying ovens and labeling machines. Known for its stable performance, high precision, and broad applicability, the company’s equipment has become a trusted solution for diverse industrial needs.

Through this classification and analysis, it is clear that screen printing machines are indispensable in modern manufacturing. They provide a robust foundation for diversified, customized, and efficient production processes. After learning about the various types of screen printing machines, do you now have a better idea of which type to choose? If you still have any questions, please feel free to contact the professional team at JUIST for assistance: sales@juistmac.com