+86-519-83387581

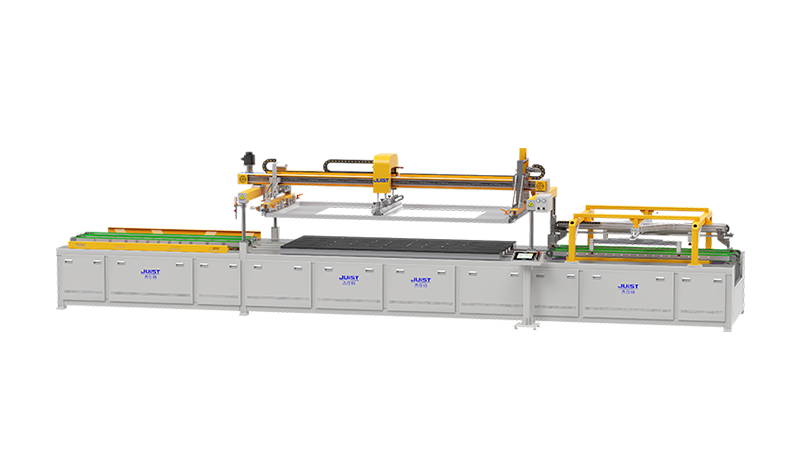

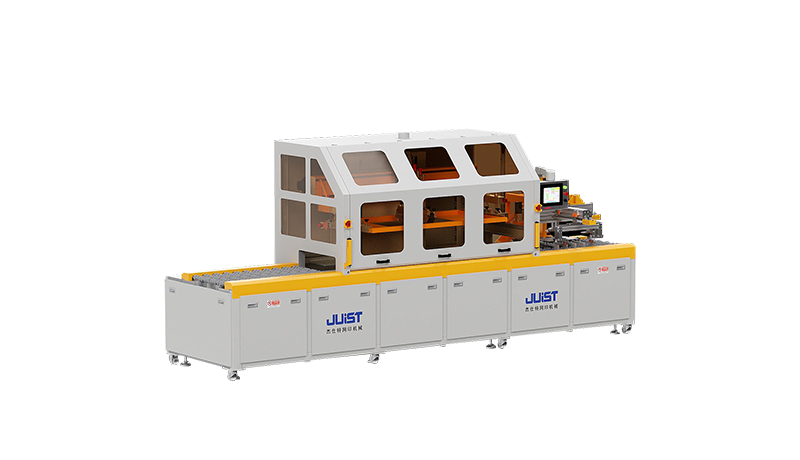

In modern industrial production, fast drying tunnel oven is widely used in food processing, pharmaceutical, chemical, electronics and other fields as an efficient and energy-saving drying equipment. One of its core advantages lies in its well-designed hot air circulation system, which evenly distributes the heat generated by the heating element to the entire furnace cavity through horizontal or vertical air transportation, ensuring that the material is heated evenly, thereby increasing the heating rate and avoiding local overheating or underheating.

1. Basic composition of hot air circulation system

The hot air circulation system of the fast drying tunnel oven is mainly composed of heating elements, fans, air ducts, temperature sensors and control systems. The heating element is responsible for generating heat, and the fan sends hot air into the furnace cavity through the air duct. The temperature sensor monitors the temperature in the furnace in real time, and the control system adjusts the power of the heating element and the speed of the fan according to the feedback of the temperature sensor to achieve precise temperature control.

2. Advantages of horizontal or vertical air transportation

The air transportation methods of the hot air circulation system are mainly divided into horizontal and vertical. The horizontal air flow method is usually suitable for tunnel furnaces with a long and moderate width. The fan blows the hot air from one end of the furnace cavity to the other end to form a horizontal hot air flow. This design can ensure that the hot air is evenly distributed in the furnace cavity and avoid temperature differences in the horizontal direction of the material. The vertical air flow method is suitable for tunnel furnaces with a higher height. The fan blows the hot air from the top or bottom of the furnace cavity to the opposite side to form a vertical hot air flow. This design can ensure that the hot air is evenly distributed up and down in the furnace cavity and avoid temperature differences in the vertical direction of the material.

3. Implementation of uniform heating

The core advantage of the hot air circulation system is that it can achieve uniform heating of the material. By precisely controlling the power of the heating element and the speed of the fan, it can ensure that the hot air flows at a constant speed and temperature in the furnace cavity, thereby avoiding local overheating or underheating. In addition, the hot air circulation system can also be personalized according to the characteristics of the material and the drying requirements, such as adjusting the shape and size of the air duct, changing the speed of the fan, etc., to achieve the best drying effect.

IV. Effects in practical applications

In practical applications, the hot air circulation system of the rapid drying tunnel furnace has shown remarkable effects. First, it greatly improves the heating rate and shortens the drying time, thereby improving production efficiency. Second, because the hot air is evenly distributed in the furnace cavity, the material is heated evenly, avoiding quality problems caused by local overheating or underheating. In addition, the hot air circulation system can also be flexibly adjusted according to the characteristics of the material and the drying requirements, realizing a personalized drying plan.