+86-519-83387581

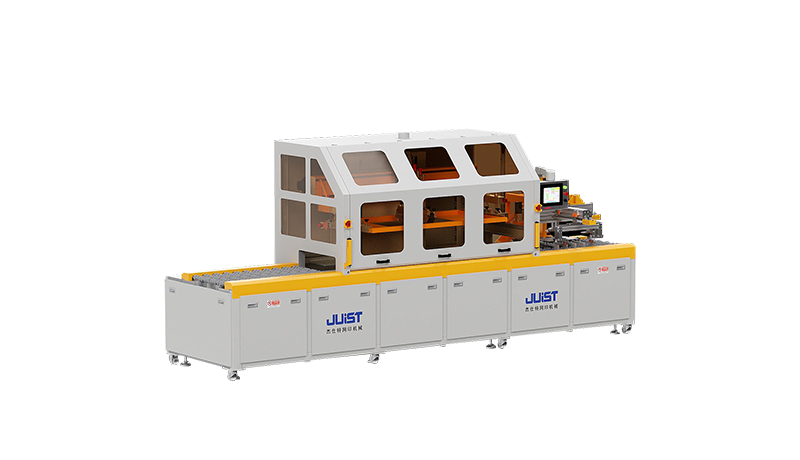

In the rapid development of the photovoltaic industry, photovoltaic glass is a key component of solar panels, and its manufacturing quality directly affects the power generation efficiency and stability of the entire photovoltaic system. Among them, the fully automatic photovoltaic glass screen printer has become an important equipment on the photovoltaic glass production line with its efficient and precise operation capabilities. The cornerstone of all these high-precision operations is the CCD (charge-coupled device) camera system it is equipped with.

As the core component of modern machine vision technology, CCD cameras play a vital role in the field of industrial automation with their high resolution, high sensitivity and image processing capabilities. In the fully automatic photovoltaic glass screen printer, the CCD camera is cleverly integrated into the equipment and is responsible for high-precision identification of marks or targets on photovoltaic glass.

These marks or targets are usually crosshairs, dots or other geometric shapes preset on the photovoltaic glass. They are like "lighthouses" guiding printing operations, located at the four corners or specific positions of the glass. These marks not only provide a clear positioning reference for the printer, but also ensure that each print can be accurately placed in the predetermined position, thus ensuring the manufacturing accuracy of photovoltaic glass.

When the photovoltaic glass is fed into the printer, the CCD camera begins its work. Like a pair of sharp eyes, it quickly and accurately captures the target image on the glass. Subsequently, through the built-in high-performance image processing technology, the CCD camera will finely compare the captured image with the preset reference position. This comparison process requires not only extremely high speed, but also unparalleled precision to ensure that any slight position deviation can be discovered and processed in time.

Once the position deviation is found, the control system of the fully automatic photovoltaic glass screen printer will immediately start the compensation mechanism. By accurately calculating the deviation amount and driving the mechanical components to make corresponding adjustments, the system can quickly align the target to the reference position. This process not only realizes the precise correction of the glass position, but also lays a solid foundation for subsequent screen printing operations.

It is worth noting that the application of CCD cameras in automatic photovoltaic glass screen printing machines is not limited to position recognition and correction. It can also monitor various parameters in the printing process, such as ink thickness, printing speed, etc. in real time to ensure the stability and consistency of printing quality. Through continuous image acquisition and analysis, the CCD camera provides rich feedback information for the printer, enabling the equipment to automatically adjust the working state according to the actual situation to achieve the printing effect.

CCD cameras play a vital role in automatic photovoltaic glass screen printing machines. With its image recognition and processing capabilities, it has led the high-precision positioning revolution in the field of photovoltaic glass manufacturing. With the continuous advancement of technology and the deepening of application, it is believed that CCD cameras will show their unique charm and value in more fields.