+86-519-83387581

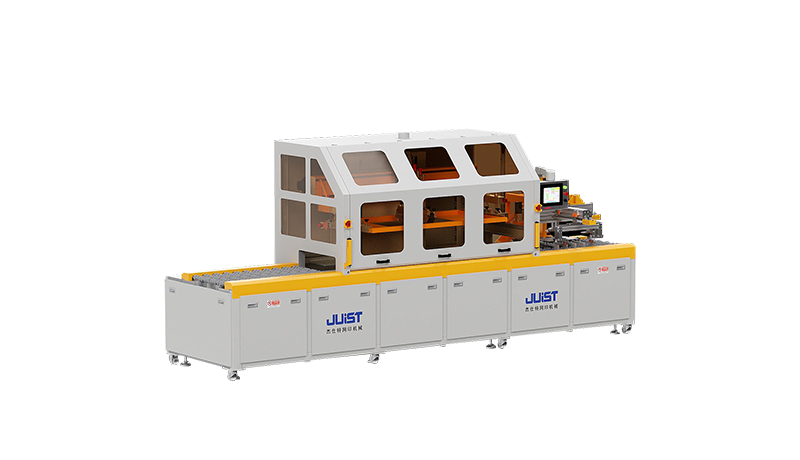

As a key equipment in the photovoltaic industry, the material selection and conservation strategy of Automatic Photovoltaic Fiberglass Sheet Screen Printing Machine in its production and use deeply reflects the concept of environmental protection and sustainability. This concept not only runs through the design and manufacturing stages of the machine, but also extends to its daily operation and maintenance, jointly building a green and efficient production system.

Material selection: environmental protection first

In terms of material selection, Automatic Photovoltaic Fiberglass Sheet Screen Printing Machine follows strict environmental protection standards. First of all, for the main structure of the machine, manufacturers tend to use high-strength, corrosion-resistant and easily recyclable metal materials such as aluminum alloy or stainless steel. These materials not only have excellent mechanical properties to ensure the stable operation and long-term durability of the machine, but also their recycling and reuse process is relatively simple, which helps to reduce resource consumption and environmental pollution.

The inks and coatings used in the printing process are also the focus of environmental protection considerations. Traditional inks often contain volatile organic compounds (VOCs), which pose a threat to the environment and human health. Modern automated photovoltaic fiberglass sheet screen printing machines widely use environmentally friendly inks, which have the characteristics of low VOCs emissions, non-toxic and harmless, and can minimize the negative impact on the environment while ensuring printing quality.

For the parts that are in direct contact with the photovoltaic fiberglass sheet, such as printing screens, scrapers, etc., manufacturers also focus on selecting wear-resistant, corrosion-resistant and easy-to-clean materials to reduce the generation of waste caused by material wear or contamination.

Material Saving: Fine Management

In terms of material saving, the Automatic Photovoltaic Fiberglass Sheet Screen Printing Machine achieves efficient use of raw materials through fine management and technological innovation. First of all, the machine adopts an advanced digital control system that can accurately control various parameters in the printing process, such as printing pressure, speed, position, etc., to ensure that every print is as close to perfect as possible. This high-precision printing technology not only improves product quality, but also reduces material waste caused by poor printing.

The machine is also equipped with an intelligent material management system that can monitor the inventory and usage of raw materials in real time and accurately allocate them according to production needs. By optimizing production plans and inventory management strategies, manufacturers can effectively avoid over-purchasing and backlog of raw materials, thereby reducing inventory costs and resource waste.

In the daily operation and maintenance of the machine, manufacturers also pay attention to the use of economical materials. For example, for parts and consumables that need to be replaced, manufacturers will give priority to alternatives that meet environmental standards and encourage users to recycle and reuse them. At the same time, manufacturers also provide professional training and guidance services to help users master the correct operation methods and maintenance skills to reduce material waste and machine failures caused by improper operation.

Automatic Photovoltaic Fiberglass Sheet Screen Printing Machine deeply embodies the concept of environmental protection and sustainability through environmentally friendly material selection and refined material saving strategies during production and use. This concept not only helps to reduce production costs and improve product quality, but also promotes the green development and sustainable development of the photovoltaic industry. With the continuous advancement of technology and the continuous growth of market demand, we have reason to believe that this environmentally friendly and efficient automated production equipment will be more widely used and promoted in the future.