+86-519-83387581

In the realm of high-tech electronics, components like light guide film (LGF) modules play a crucial role in enhancing the user experience by improving the illumination of keyboards and laptop screens. LGF modules distribute light evenly, allowing for efficient backlighting without adding significant bulk to the device. Roll-to-roll (R2R) screen printing has emerged as a leading method for manufacturing these modules, providing the precision, scalability, and durability needed for modern electronic devices.

The Importance of Light Guide Film (LGF) Modules

LGF modules are essential for backlighting in devices like keyboards and laptops, enabling a sleek, low-profile design while ensuring uniform lighting. They work by guiding light from an LED source across a thin film, dispersing it evenly to eliminate hotspots and shadows. This is particularly important for devices where aesthetics and usability go hand in hand, such as gaming keyboards and premium laptops.

Why Roll-to-Roll Screen Printing?

Roll-to-roll screen printing is ideally suited for the production of LGF modules due to its ability to deliver highly precise, consistent patterns at scale. Here’s why this technology stands out:

1. Precision and Uniformity: LGF modules require exacting precision to ensure that the light is evenly distributed across the film. R2R screen printing excels at creating uniform micro-patterns on flexible films, which are critical for guiding light effectively. The fine mesh used in screen printing ensures high resolution and accuracy in the deposition of inks or conductive materials on the film.

2. Efficiency and Scalability: R2R screen printing allows for continuous production, making it highly efficient for large-scale manufacturing. This process minimizes waste and reduces setup times, allowing manufacturers to produce large volumes of LGF modules without sacrificing quality. In a competitive market where speed and cost-efficiency are key, this is a significant advantage.

3. Durability and Performance: LGF modules are often exposed to constant use and varying environmental conditions. R2R screen printing uses durable, high-performance inks that can withstand wear and tear while maintaining their reflective or light-guiding properties. This ensures that the backlighting in keyboards and laptops remains consistent over time, even with heavy use.

4. Customization and Flexibility: The versatility of roll-to-roll screen printing allows for easy customization of LGF module designs. Manufacturers can adjust the printing process to accommodate different device specifications, from ultrathin laptops to ergonomically designed keyboards. This adaptability ensures that the technology meets the diverse needs of high-tech electronics manufacturers.

Enhancing User Experience

The precision of roll-to-roll screen printing directly impacts the end-user experience. In backlit keyboards, for instance, poorly distributed lighting can result in uneven brightness, making it harder to see the keys in low-light conditions. By using R2R screen printing for LGF modules, manufacturers can ensure that each key is evenly illuminated, improving visibility and user satisfaction. The same applies to laptops, where consistent backlighting enhances both the functionality and aesthetic appeal of the device.

Sustainability and Cost Efficiency

Roll-to-roll screen printing is also aligned with sustainable manufacturing practices. The process uses less material and generates less waste compared to other methods, making it a more environmentally friendly option. Additionally, the cost savings from increased production efficiency and reduced material waste make R2R printing an economically viable solution for producing LGF modules at scale.

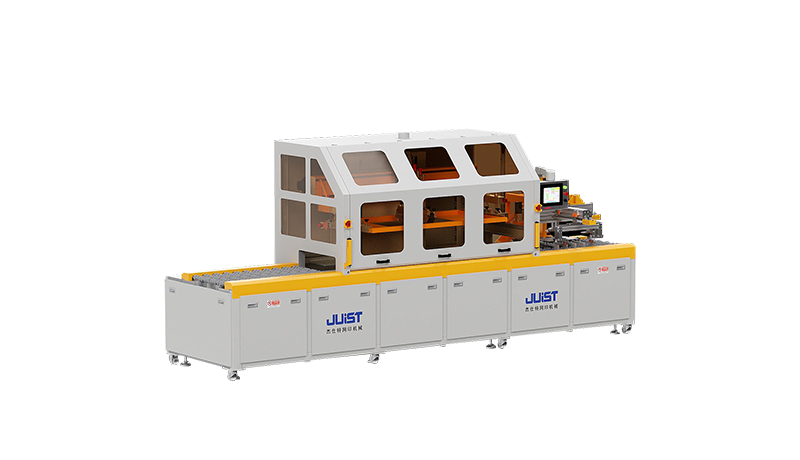

We invite you to visit JUIST to reserve your keyboards printing equipment. For more information you can also reach us on WhatsApp: +86 18101500471 or via email at sales@juistmac.com.