+86-519-83387581

In the world of modern display technology, precision and quality are key to creating visually stunning, energy-efficient screens. One critical component in achieving this is the diffuser film, which plays a vital role in dispersing light evenly across the screen, ensuring clarity and brightness while minimizing glare. Roll-to-roll (R2R) screen printing technology has emerged as an advanced method for producing diffuser films, offering unparalleled efficiency, precision, and scalability in the manufacturing process.

The Role of Diffuser Films in Display Screens

Diffuser films are essential components in display screens, particularly in devices like smartphones, TVs, tablets, and computer monitors. These films work by scattering light from the backlight unit (BLU) evenly across the display, creating a uniform brightness and reducing any harsh hotspots or shadows. A well-designed diffuser film enhances the viewing experience by improving image clarity, contrast, and color accuracy, all while conserving energy by distributing light efficiently.

Advantages of Roll-to-Roll Screen Printing for Diffuser Films

The roll-to-roll screen printing process is perfectly suited for manufacturing diffuser films for display screens, thanks to several key advantages:

1. Precision and Consistency: Diffuser films require intricate micro-patterns to scatter light effectively. Roll-to-roll screen printing is highly precise, capable of producing consistent, high-resolution patterns that ensure even light distribution across the entire display. The fine mesh screens used in this process allow for accurate ink deposition, ensuring that each diffuser film meets strict quality standards.

2. High-Volume Efficiency: One of the greatest strengths of roll-to-roll screen printing is its ability to produce large volumes of material quickly and efficiently. In the display industry, where demand for high-quality components is constant, R2R printing allows manufacturers to meet production targets without sacrificing quality. This continuous printing process minimizes downtime and reduces setup times, making it a cost-effective solution for large-scale manufacturing of diffuser films.

3. Scalability: As the demand for display technology grows, particularly in sectors such as consumer electronics, automotive displays, and digital signage, scalability becomes crucial. Roll-to-roll screen printing supports the mass production of diffuser films, making it easy for manufacturers to scale operations to meet market demand while maintaining consistent product quality.

4. Material Versatility: Roll-to-roll screen printing can handle a variety of flexible substrates, which is essential when producing diffuser films for different types of displays. Whether the film needs to be ultra-thin for use in smartphones or more rigid for larger displays like televisions, R2R screen printing offers the versatility needed to print on various materials without compromising on quality.

5. Durability and Performance: Diffuser films must be durable enough to withstand the heat and wear of display operation while maintaining their optical properties over time. R2R screen printing uses durable inks and coatings designed to enhance the lifespan and performance of diffuser films, ensuring that the films remain effective throughout the display’s lifecycle.

Enhancing Display Performance and User Experience

The precision of roll-to-roll screen printing directly influences the performance of display screens. With a well-printed diffuser film, display manufacturers can achieve better light uniformity, higher energy efficiency, and sharper images. This improves the overall user experience, whether the display is being used in a smartphone, television, or high-end computer monitor. Additionally, enhanced light diffusion contributes to better color reproduction, which is crucial for applications that demand accurate color fidelity, such as professional graphics or video editing.

Cost Efficiency and Sustainability

Roll-to-roll screen printing offers significant cost savings over traditional printing methods due to its continuous process and efficient use of materials. With less waste generated during production and a more streamlined workflow, manufacturers can reduce both production costs and environmental impact. As sustainability becomes a more prominent concern across industries, the ability of R2R printing to produce high-quality diffuser films with minimal waste makes it an eco-friendly choice for display manufacturers.

Applications in Emerging Display Technologies

As display technologies evolve, such as the development of OLED and microLED screens, the need for more advanced and precise diffuser films continues to grow. Roll-to-roll screen printing’s ability to print intricate patterns at high volumes makes it an ideal technology for these next-generation displays, where even slight variations in light diffusion can affect overall performance. By using R2R printing, manufacturers can ensure that their diffuser films meet the high demands of these emerging technologies, paving the way for brighter, more energy-efficient, and visually stunning displays.

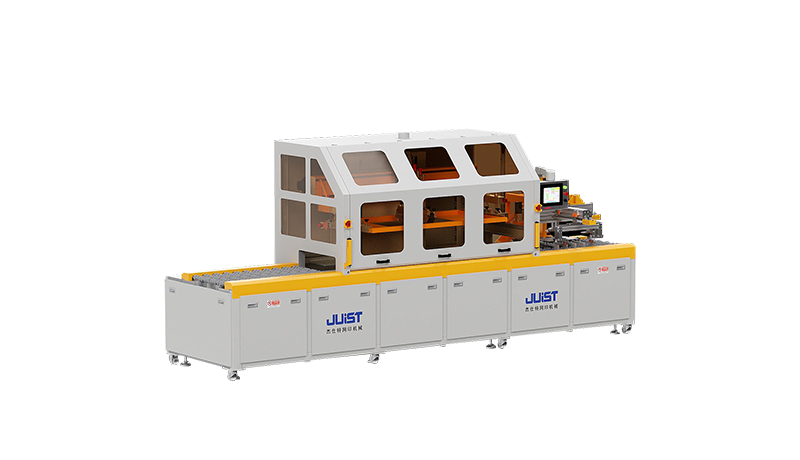

We invite you to visit JUIST to reserve your diffuser film printing equipment. For more information you can also reach us on WhatsApp: +86 18101500471 or via email at sales@juistmac.com.