+86-519-83387581

In the rapidly evolving world of consumer electronics, laptops have become essential tools for work, education, and entertainment. As these devices become more compact, powerful, and energy-efficient, the need for innovative manufacturing technologies has grown. One technology that is making a significant impact in the production of laptop circuits is Roll-to-Roll (R2R) screen printing. This advanced manufacturing process is transforming how flexible printed circuits (FPCs) are produced, offering unprecedented advantages in terms of precision, scalability, and cost-effectiveness.

The Importance of Flexible Printed Circuits (FPCs) in Laptops

Flexible printed circuits are essential to modern laptop design. Unlike traditional rigid printed circuit boards (PCBs), FPCs allow for the creation of complex, three-dimensional designs that fit into the increasingly slim and lightweight profiles of laptops. FPCs enable flexible connections between different components, such as the motherboard, display, and battery, all while ensuring high levels of performance and durability.

FPCs are typically made from flexible substrates like polyimide films, onto which conductive materials are printed. Given their critical role in laptop functionality, the production of these circuits must meet exacting standards for precision, durability, and efficiency. This is where Roll-to-Roll screen printing excels.

Why Roll-to-Roll Screen Printing?

Roll-to-roll screen printing is a continuous process where flexible substrates are fed through a printing machine that applies circuit patterns onto the material using precision mesh screens. This method is ideal for printing circuits on flexible materials and offers several key advantages over traditional manufacturing techniques.

1. High Precision: Roll-to-roll screen printing allows for the production of intricate and highly precise circuit patterns. This is particularly important for laptops, where space is at a premium and circuits need to fit into compact designs without sacrificing performance. The ability to print with high accuracy ensures that every circuit meets the strict electrical requirements of modern laptops.

2. Scalability for Mass Production: One of the most significant benefits of R2R screen printing is its scalability. The continuous nature of the process allows manufacturers to produce large volumes of flexible circuits efficiently, making it possible to meet the high demand for laptops in the global market. As consumer demand for faster and more powerful devices increases, manufacturers need to scale up production without compromising on quality, and R2R printing offers the perfect solution.

3. Cost-Effectiveness: Roll-to-roll screen printing reduces material waste and lowers setup costs compared to traditional methods like lithography. The continuous process eliminates the need for multiple stops and starts, which are common in batch processing. This not only speeds up production but also minimizes material usage, making the process more environmentally friendly and cost-effective. For manufacturers, these savings can be passed on to consumers, allowing for the production of high-quality laptops at more competitive prices.

4. Customization and Versatility: The flexibility of roll-to-roll screen printing allows manufacturers to easily modify circuit designs to meet the specific needs of different laptop models. Whether it's a gaming laptop that requires high-speed data transfer or an ultrabook that prioritizes energy efficiency and compactness, R2R printing can adapt to a wide range of specifications. This versatility is essential in today’s fast-paced electronics market, where product lifecycles are short and manufacturers need to quickly respond to new trends and technologies.

Impact on Laptop Performance and Design

The use of roll-to-roll screen printing in laptop circuit manufacturing directly enhances both the performance and design of the devices. Flexible printed circuits produced through R2R printing are not only lighter and thinner than traditional PCBs, but they are also more durable and resistant to wear and tear. This durability is crucial for laptops, which are portable devices often subjected to frequent movement, vibrations, and temperature changes.

Furthermore, the precision offered by R2R screen printing ensures that circuits can handle high-speed data transmission and power management more efficiently. This improves overall system performance, allowing for faster processing speeds, better battery life, and enhanced heat dissipation. As laptops become more powerful, these improvements in circuit performance are essential to maintaining the reliability and functionality of the device.

The ability to create more compact and lightweight circuits also opens up new design possibilities. Laptop manufacturers can design thinner and sleeker devices without compromising on performance, a trend that has become increasingly important in the consumer electronics market. With R2R screen printing, manufacturers can push the boundaries of design, creating devices that are not only functional but also aesthetically appealing.

Sustainability and Environmental Benefits

In addition to its technical and economic advantages, roll-to-roll screen printing offers significant environmental benefits. The reduction in material waste during the printing process helps minimize the environmental impact of manufacturing. Moreover, the energy-efficient nature of the process, combined with the ability to produce lightweight and energy-saving circuits, contributes to the overall sustainability of the product lifecycle.

As consumers and companies alike become more conscious of environmental issues, the ability to produce high-tech devices in a more sustainable manner is a key competitive advantage. Roll-to-roll screen printing aligns with the growing demand for eco-friendly manufacturing practices, positioning it as a forward-thinking solution for the future of electronics manufacturing.

The Future of Laptop Circuit Manufacturing

As the demand for laptops continues to rise, driven by trends such as remote work, gaming, and online education, the need for efficient and innovative manufacturing processes will only grow. Roll-to-roll screen printing is poised to play a central role in meeting these demands by offering a scalable, cost-effective, and precise method for producing flexible printed circuits.

Looking ahead, the integration of R2R printing with other advanced manufacturing technologies, such as automated inspection systems and AI-driven quality control, could further enhance the capabilities of this process. These innovations would allow for even greater precision and efficiency, ensuring that laptop manufacturers can continue to meet the evolving needs of consumers while maintaining high standards of quality and performance.

Roll-to-roll screen printing is revolutionizing the way laptop circuits are manufactured, offering a range of benefits that make it an ideal solution for producing flexible printed circuits. From its ability to deliver precise and durable circuit patterns to its scalability and cost-efficiency, R2R printing is driving the next generation of laptop design and performance. As the demand for more compact, powerful, and energy-efficient devices continues to grow, roll-to-roll screen printing will remain at the forefront of circuit manufacturing, shaping the future of laptop technology.

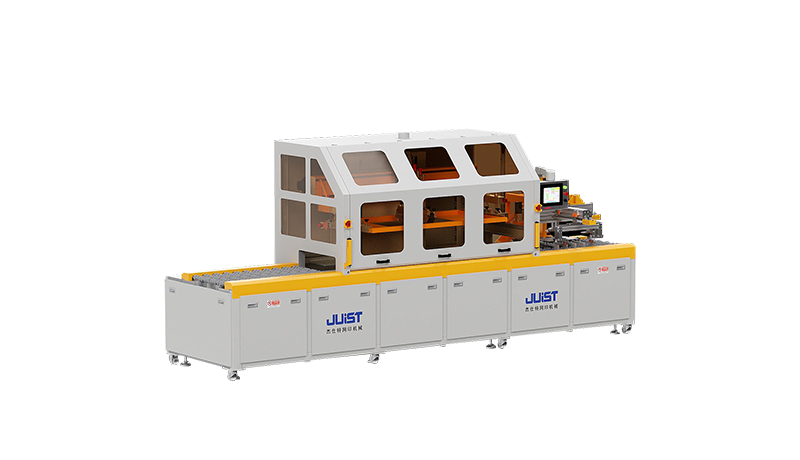

We invite you to visit JUIST to reserve your flexible printed circuits printing equipment. For more information you can also reach us on WhatsApp: +86 18101500471 or via email at sales@juistmac.com.