+86-519-83387581

The rise of the Internet of Things (IoT) and smart technologies has placed Radio Frequency Identification (RFID) tags at the forefront of industries such as supply chain management, logistics, retail, healthcare, and asset tracking. These tags allow for contactless data transmission, enhancing operational efficiency by enabling real-time tracking and monitoring. As demand for RFID technology grows, manufacturers are seeking faster, more cost-effective, and scalable methods to produce RFID tags in large volumes. This is where Roll-to-Roll (R2R) screen printing technology shines, offering high precision, efficiency, and flexibility in RFID tag production.

RFID Tag Production and Its Challenges

An RFID tag is typically composed of an antenna and an integrated circuit (IC). The antenna is crucial for transmitting and receiving signals between the IC chip and an RFID reader. High precision in the manufacturing of the antenna is essential for optimal performance, ensuring that signals are transmitted accurately and efficiently. The challenge in RFID tag production lies in the ability to produce these antennas in mass quantities while maintaining consistency, quality, and cost-effectiveness.

Traditional methods like chemical etching and photolithography, though effective, can be time-consuming, costly, and environmentally unfriendly. As a result, manufacturers have turned to Roll-to-Roll screen printing, a continuous process that offers high throughput and scalability, without sacrificing the quality and precision required for RFID antennas.

Advantages of Roll-to-Roll Screen Printing in RFID Tag Production

Roll-to-Roll screen printing offers several key advantages for the production of RFID tags, making it a preferred solution for many manufacturers:

1. High Production Speed and Scalability

Roll-to-Roll screen printing enables continuous printing on flexible substrates, making it ideal for mass production. This high-speed process allows manufacturers to produce thousands of RFID tags per hour, significantly increasing efficiency compared to traditional methods. The ability to scale production quickly while maintaining quality makes R2R screen printing particularly valuable in industries with rapidly growing RFID demands.

2. Precision and Consistency

Precision is crucial in RFID antenna design, as even the smallest variation can impact the performance of the tag. R2R screen printing ensures consistent and accurate patterns through the use of finely controlled mesh screens and conductive inks. This method guarantees that each antenna is produced to exact specifications, maintaining the reliability and performance of the RFID tags.

3. Cost-Effectiveness

Traditional manufacturing methods often require multiple steps, specialized equipment, and substantial material use, which can drive up costs. In contrast, Roll-to-Roll screen printing reduces material waste by directly applying conductive inks to the substrate in a single step. The continuous nature of the process also minimizes downtime and labor costs, offering manufacturers a more cost-effective solution for producing high volumes of RFID tags.

4. Versatility with Materials

One of the major benefits of R2R screen printing is its ability to print on a wide range of flexible substrates, such as paper, plastic film, and fabric. This versatility allows manufacturers to tailor RFID tags for different applications, whether they need to produce tags for retail inventory management, logistics tracking, or medical device identification. The ability to customize RFID tags for various industries further expands the use cases for Roll-to-Roll printing in RFID production.

5. Sustainability

In addition to its efficiency and cost advantages, Roll-to-Roll screen printing is a more environmentally friendly process compared to traditional methods like chemical etching, which can produce harmful waste. The use of conductive inks in R2R printing reduces the need for harsh chemicals, while the streamlined process minimizes material wastage. This focus on sustainability aligns with the growing demand for eco-friendly manufacturing practices across industries.

Conductive Inks: A Key Component

Conductive inks are the heart of the Roll-to-Roll screen printing process, playing a crucial role in the performance of RFID antennas. These inks, typically made from materials such as silver, copper, or carbon, are applied to the substrate through the printing mesh to create the circuit for the RFID antenna. The high conductivity of these inks ensures efficient signal transmission, which is essential for the effective operation of RFID tags.

Advances in nanotechnology have improved the performance of conductive inks, enabling the creation of thinner, more flexible, and more durable RFID antennas. These innovations have also helped reduce the cost of materials, making R2R printing even more attractive for large-scale RFID tag production.

Applications of RFID Tags in Various Industries

RFID technology has a wide range of applications, and Roll-to-Roll screen printing allows manufacturers to meet the specific needs of each industry:

1. Retail: RFID tags are commonly used in retail for inventory management, loss prevention, and enhancing the shopping experience. With R2R screen printing, retailers can access cost-effective, high-quality tags that ensure real-time tracking of goods and streamline operations.

2. Logistics and Supply Chain Management: In logistics, RFID tags are used to track shipments, manage inventory, and ensure supply chain transparency. The ability of R2R screen printing to produce durable, reliable tags makes it ideal for the fast-paced and demanding logistics environment.

3. Healthcare: RFID tags are used to track medical devices, pharmaceuticals, and patient information. The precision and flexibility of R2R screen printing allow for the creation of RFID tags that are compatible with the sensitive and regulated nature of the healthcare industry.

4. Asset Tracking and Security: Companies use RFID tags to manage and secure valuable assets, from industrial equipment to high-value electronics. R2R screen printing can produce robust, long-lasting tags that ensure effective asset tracking and protection.

The Future of Roll-to-Roll Screen Printing in RFID Production

As RFID technology continues to evolve and expand into new markets, the demand for more efficient, scalable production methods will only increase. Roll-to-Roll screen printing is poised to meet this demand by offering a flexible, cost-effective, and sustainable solution for RFID tag manufacturing.

Future advancements in conductive inks and printing technology will further enhance the capabilities of R2R screen printing, allowing for even more precise, high-performance RFID tags. Additionally, as industries increasingly prioritize sustainability, the environmentally friendly nature of Roll-to-Roll printing will position it as a preferred choice for manufacturers looking to reduce their ecological footprint.

Roll-to-Roll screen printing is transforming the production of RFID tags, providing a solution that balances high precision, efficiency, and scalability. With the ability to produce cost-effective, high-quality tags on a wide range of materials, R2R screen printing is helping to drive the widespread adoption of RFID technology across various industries. As demand for RFID tags grows, Roll-to-Roll screen printing will continue to play a key role in shaping the future of RFID manufacturing, delivering both operational and environmental benefits to manufacturers and end-users alike.

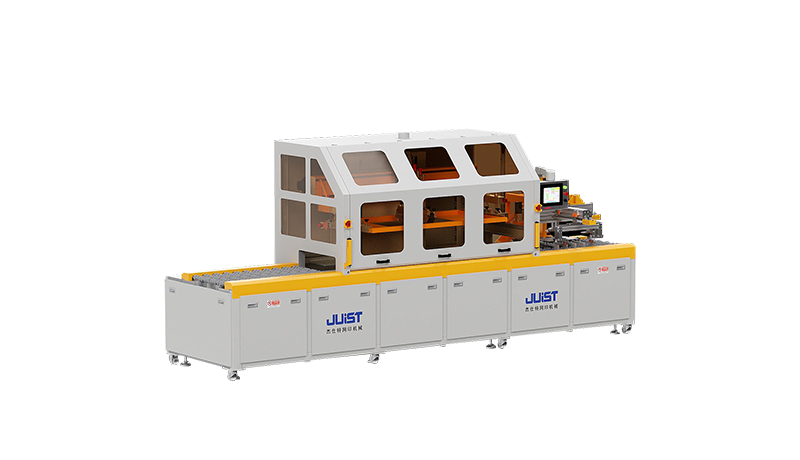

We invite you to visit JUIST to reserve your RFID tags printing equipment. For more information you can also reach us on WhatsApp: +86 18101500471 or via email at sales@juistmac.com.