+86-519-83387581

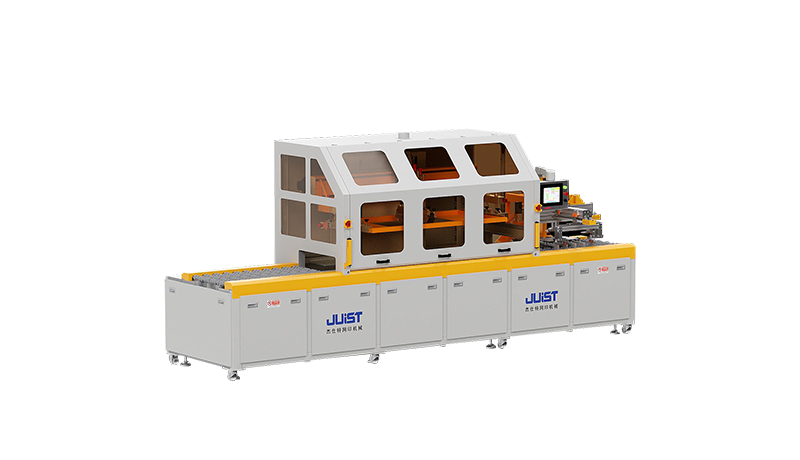

1. Fully automatic printing press: the crystallization of technological innovation

The fully automatic photovoltaic glass screen printing machine, as one of the core equipment of the modern automated production line, integrates many high-tech technologies such as precision machinery, electronic control, image processing and advanced software algorithms. The original intention of its design is to overcome the shortcomings of low production efficiency, high labor costs, and unstable quality in traditional semi-automatic or manual printing methods. Through a highly integrated automated control system, the equipment can achieve precise adjustment and real-time monitoring of printing parameters, ensuring that every printing can meet the accuracy and consistency of the design requirements.

2. Significant improvement in production efficiency

Compared with semi-automatic or manual printing methods, fully automatic photovoltaic glass screen printing machines have particularly outstanding advantages in production efficiency. First of all, the automated process greatly reduces manual operations. From glass loading, positioning, printing to unloading, the entire process requires almost no manual intervention, significantly improving the continuous operation capability of the production line. Secondly, the advanced motion control system and servo drive technology greatly increase the printing speed. Even in the face of large-scale production tasks, it can be completed in a very short time, effectively shortening the product delivery cycle.

More importantly, the application of fully automatic equipment also reduces the error rate caused by human factors and improves the consistency of product quality. In the printing process of photovoltaic glass, key factors such as the clarity of the pattern, the uniformity of the lines and the adhesion of the ink can be optimized through precise control, thereby ensuring that each piece of photovoltaic glass can meet strict quality standards, providing The efficient power generation of photovoltaic modules provides a solid guarantee.

3. Cost Savings and Sustainable Development

From the perspective of cost-benefit analysis, although the initial investment of a fully automatic photovoltaic glass screen printing machine is relatively high, the long-term returns it brings are obvious. On the one hand, by improving production efficiency, companies can produce more products in the same time and increase sales revenue; on the other hand, reducing manpower requirements reduces labor costs, while reducing rework and material waste caused by quality problems, further compressing production costs.

In addition, the application of fully automatic production lines is also in line with the current trend of manufacturing industry transforming into intelligent and green. By optimizing the production process and reducing energy consumption and waste emissions, the fully automatic photovoltaic glass screen printing machine also plays an active role in promoting the sustainable development of the photovoltaic industry.