+86-519-83387581

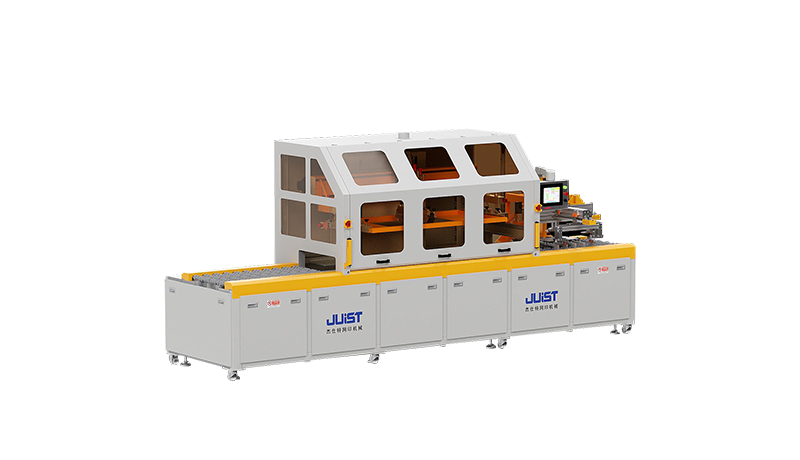

Adjustable printing platform: the key to adapting to various thicknesses

A major highlight of the fully automatic two-color glass screen printing machine is its adjustable printing platform. This design fully takes into account the diversity of glass substrates in thickness. In actual production, the thickness of glass substrates may vary from ultra-thin (such as mobile phone screen covers) to relatively thick (such as architectural glass), which places extremely high demands on the adaptability of printing equipment. Traditional printing equipment often finds it difficult to maintain consistent printing quality over such a wide range of thicknesses.

The fully automatic two-color glass screen printing machine can easily adjust the height of the printing platform through a precise adjustment mechanism to ensure that the printing screen and the glass substrate always maintain the best contact distance. This fine-tuning ability not only helps to avoid uneven ink distribution caused by uneven substrates during printing, but also effectively reduces glass damage or ink penetration caused by excessive pressure, thereby ensuring the clarity and integrity of the printed pattern.

Pressure control system: the secret to ensuring uniform ink distribution

In addition to the adjustable printing platform, the fully automatic two-color glass screen printing machine is also equipped with an advanced pressure control system. The system can accurately control the downward pressure of the scraper during the printing process according to the preset parameters, ensuring that the ink can be evenly and stably transferred to the glass surface through the screen. The realization of this function relies on high-precision sensors and closed-loop feedback mechanisms, which can monitor and adjust the pressure of the scraper in real time, maintaining extremely high printing accuracy even at high speeds.

For glass substrates as thin as paper, excessive pressure may cause the substrate to crack or deform, while too little pressure may not be able to fully transfer the ink, affecting the printing effect. The pressure control system of the fully automatic two-color glass screen printing machine can find the perfect balance between the two through fine adjustment, so that even the most fragile glass materials can complete the printing task safely and with high quality.

Flexible response to improve production efficiency and quality

Thanks to the adjustable printing platform and pressure control system, the fully automatic two-color glass screen printing machine can show extremely high flexibility and adaptability when facing glass substrates of different thicknesses and materials. This not only means that the compatibility of the production line has been greatly improved, and it can handle more types of glass products, but also means that the number of equipment changes or settings adjustments during the production process is reduced, thereby significantly improving production efficiency.

In addition, high-quality printing effect is also an advantage that cannot be ignored by the fully automatic two-color glass screen printing machine. Whether it is a fine pattern, text or a complex color combination, it can be accurately reproduced on the glass surface, meeting the market's demand for personalized and high-end glass products.